High Heat-resistant Resin Benzoxazine P-d, F-a, ALP-d

-

Benzoxazine is a thermosetting resin with high heat resistance (Tg 100°C or higher).

-

It is characterized by high dimensional stability,high flame retardance,low dielectric loss tangent,high dustiness, andlow water absorption.

-

Copolymerization with epoxy resins, phenolic resins, etc. is possible.Particularly effective as a cross-linking agent for bismaleimide resins.

For more information,click here.

-

-

-

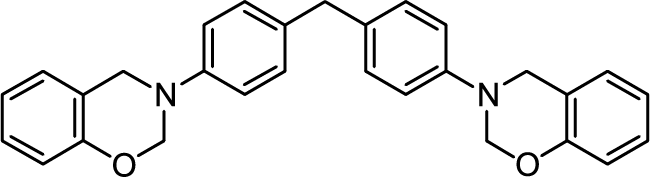

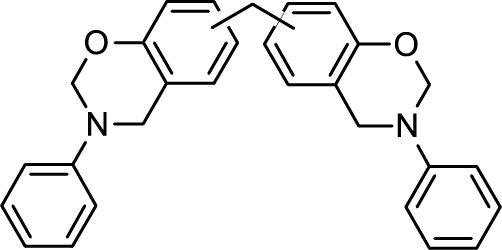

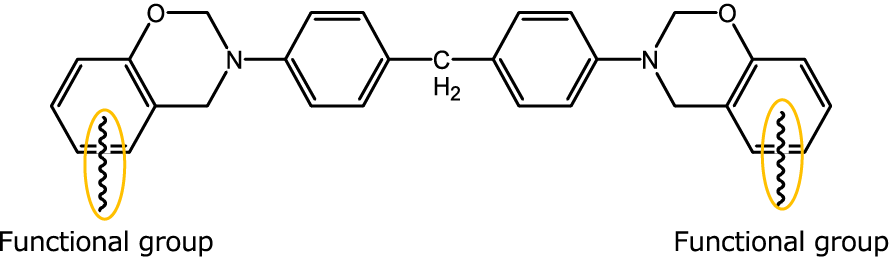

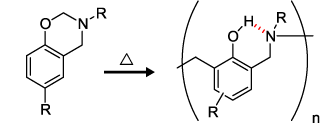

Benzoxazine curing reaction

The benzoxazine ring is opened by heat, and the polymerization reaction proceeds.

Application

-

Various electronic substrate materials

-

For Power Module Encapsulating Materials

-

Resins for CFRP

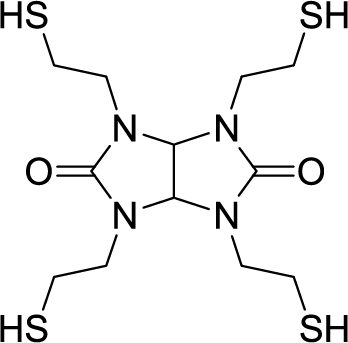

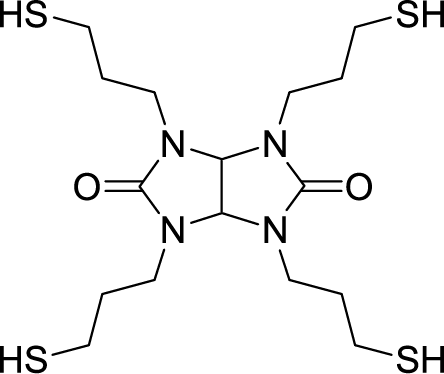

Multifunctional Thiol Epoxy Resin Curing and Cross-linking Agents TS-G,C3TS-G

-

It has high curability against epoxy resins and can be cured at low temperatures and quickly.

-

Epoxy cured materials with high moisture resistance,high heat resistance,high mechanical strength, etc. can be obtained.

-

C3TS-G is a liquid, low-viscosity compound at room temperature and has excellent handling properties.

-

-

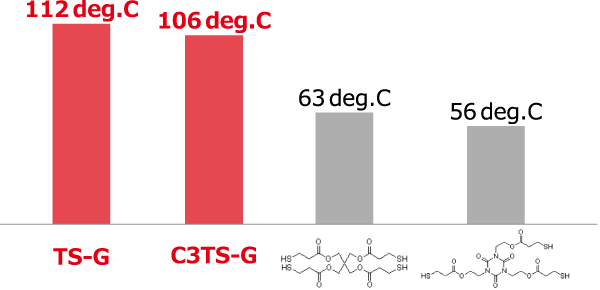

Comparison of cured material heat resistance (Tg/DMA)

Cured products with BisA epoxy have a Tg of 100°C or higher.

* N,N-Dimethylbenzylamine

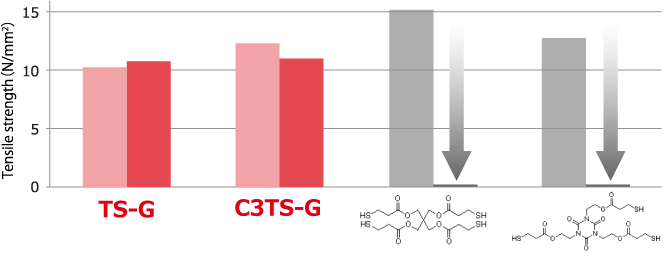

Comparison of moisture resistance (adhesive strength around 120°C/100%RT/48hrs)

No decrease in adhesive strength is observed even after a moisture resistance (PCT) test.

* N,N-Dimethylbenzylamine

Application

-

Low temperature curing adhesives Adhesive sheet

-

Display Materials

-

Various film materials

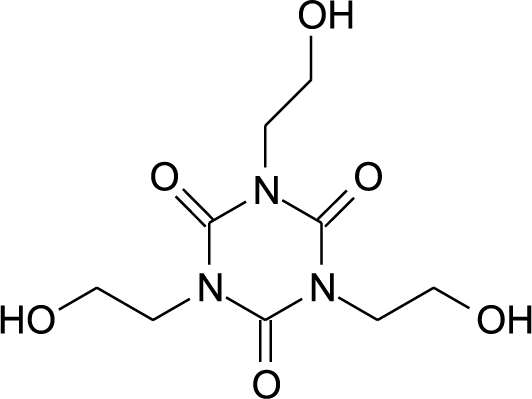

THEIC

-

It can be used for UV curing resin raw materials, insulating varnishes, and PVC stabilizers.

-

It gives excellent properties such as heat resistance, plasticity, adhesion, hardness, and gloss.

-

White crystaline granula or power

characteristics

| Product name | THEIC-G | THEIC-PW | |

|---|---|---|---|

| appearance | White crystalline granules | White crystalline powder | |

| molecular weight | 261.22 | ||

| hydroxyl value | 645 | ||

| Solubility (g/100g at 25°C) | ethanol | 5.7 | |

| acetone | 1.9 | ||

| water | 119.0 | ||

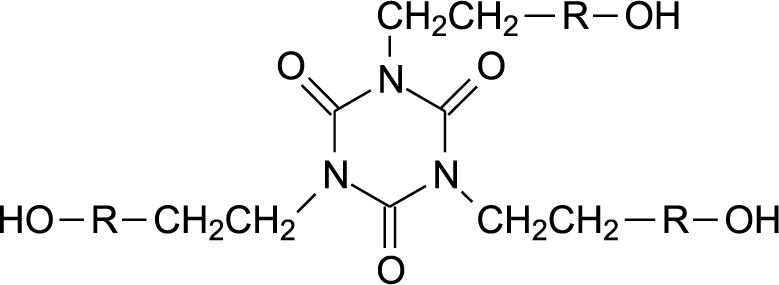

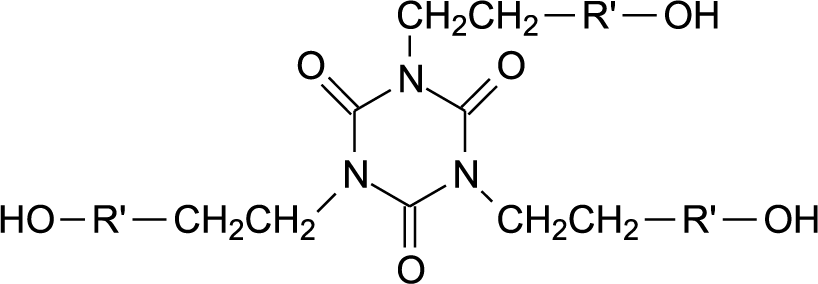

Heat-resistant Multifunctional polyol Liquid THEIC

-

Liquid THEIC is available in two grades, THEIC-LD and THEIC-EP.

-

It can be used as a raw material for polyurethane and polyester, it can provide heat resistance, flame retardance, and weather resistance.

-

Liquefaction of THEIC is expected to improve workability and expand the range of application.

-

-

characteristics

| Product name | THEIC-LD | THEIC-EP |

|---|---|---|

| appearance | Light yellow transparent viscous liquid | Yellowish brown transparent viscous liquid |

| average molecular weight | 561~673 | 435~494 |

| Hydroxyl value (mgKOH/g) | 250~300 | 330~380 |

| Acid value (mgKOH/g) | <10 | <10 |

| Viscosity (Pa-s) | 14.5(25℃) | 65.0(25℃) |