Microetching solution

"Glibrite" GB series

GB series are developed by our organic synthesis technology.

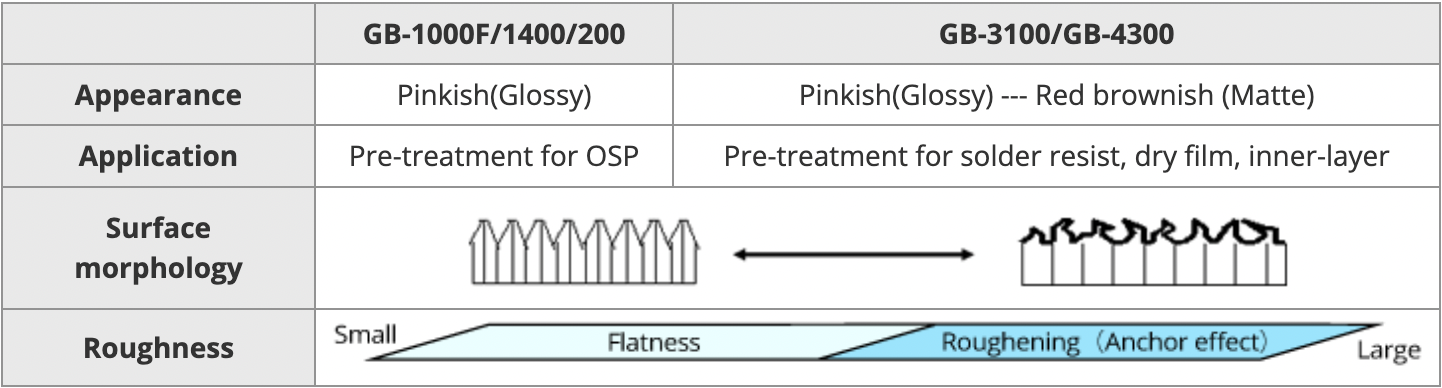

GB series achieve the optimum copper surface roughness for various applications.

Microetching solution

Glibrite GB‒1000F/GB‒1400

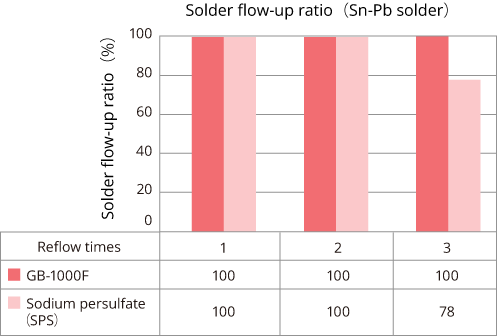

GB-1000F/GB-1400 are H2O2/H2SO4 system microetching solution. Good compatibility for pretreatment of OSP, HASL and metalic plating.

Especially GB-1000F/GB-1400 are good compatibility with OSP and achieve high performance.

In addition, GB-1400 prevents over-etching trouble caused by galvanic effect leads to reliable PWBs.

Advantages

-

-

Good compatibility with Glicoat series OSP and excellent solderability

-

Excellent anti chlorine resistance, possible using city water (GB-1400)

-

Preventing over-etching trouble caused by galvanic effect leads to reliable PWBs (GB-1400)

-

Possible to provide additive chemical only

-

Solderability

Etching amount:2.0μm

Glicoat-SMD F2 OSP thickness:0.20μm

Test coupon FR-4, t=1.2mm, Ø=0.60mm, 261 holes

Microetching chemical for OSP

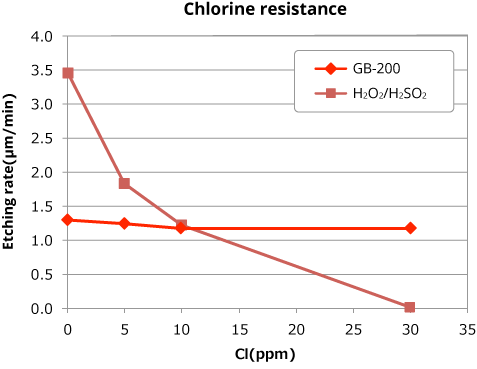

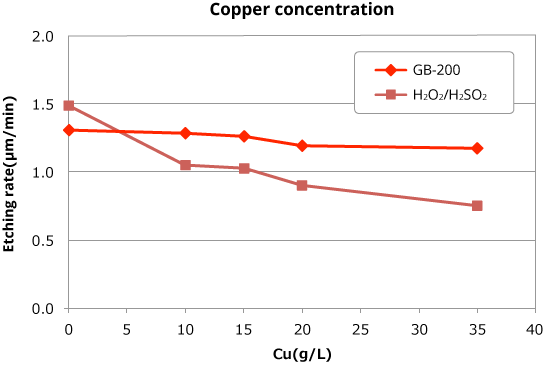

Glibrite GB-200

Suitable microetching chemical for OSP because of stable etching speed and uniform copper surface topology even high copper ion concentration.

Advantages

-

-

Uniform and smooth copper surface topology even low etching amount.

-

Stable etching rate even chlorine contamination.

-

Stable etching speed makes easy maintenance and dissoves easily.

-

Copper surface topography

Pretreatment for Dry film

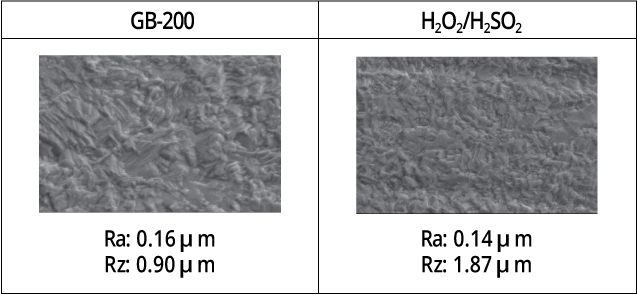

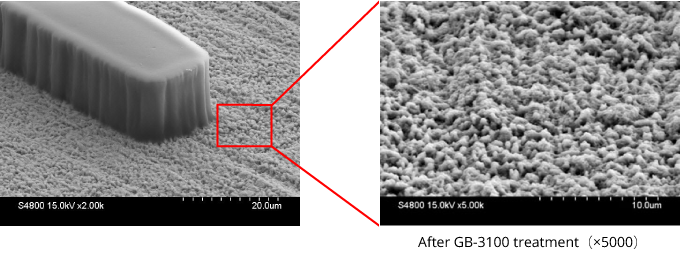

Glibrite GB‒3100

Glibrite GB-3100 is copper surface roughening solution for dry film pretreatment of patterning dry film and form uniform and fine roughening morphology even with low etching amount.

Advantages

-

-

Excellent adhesion between copper and dry film with low etching amount

-

Low defect rate of AOI due to brighter copper appearance

-

Much lower running cost by using additive type

-

Solder resist Pretreatment for PWB and IC substrate

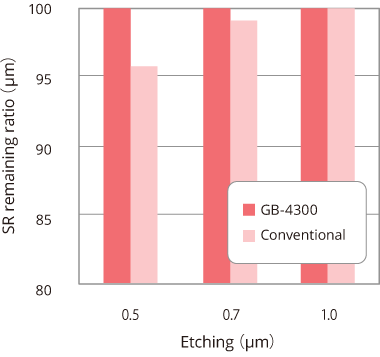

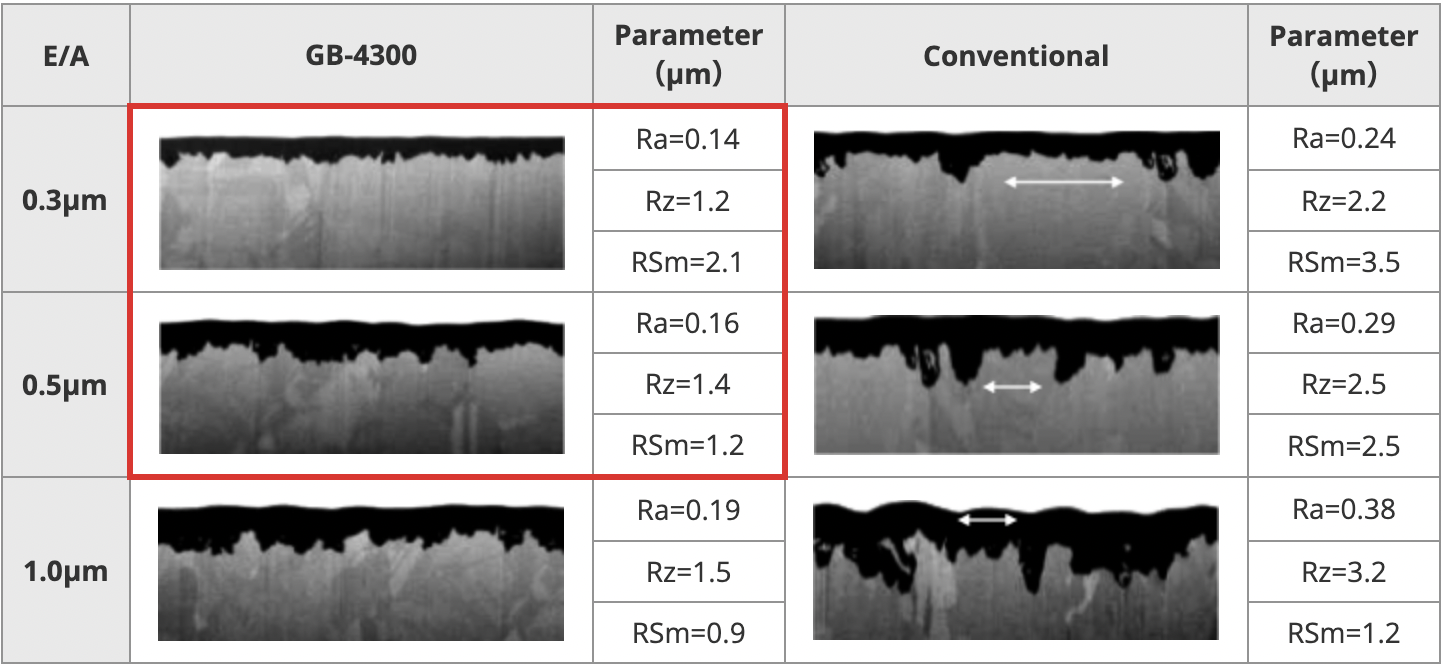

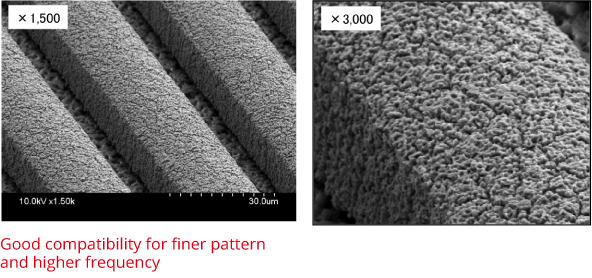

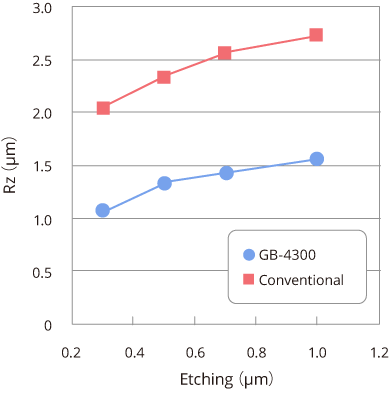

Glibrite GB‒4300

Glibrite GB-4300 is an additive for copper roughening solution based on H2O2/H2SO4 system, which is designed for solder resist or inner-layer resin preparation, in order to give the best adhesion with lower etching amount.

Advantages

-

-

Excellent solder resist adhesion with much less etching amount than conventional products

-

Suitable for super fine copper circuit and higher frequency requirement, because of lower roughness

-

Good stability in high copper concentration achieves low running cost

-

Property

Appearance

Copper roughness(Rz)

Solder resist adhesion after Gold planting