Surface treatment chemicals for PWBs

What's OSP

OSP coating protects copper surface from oxidation to keep excellent solderability and plays a prominent role in component mounting process.

Basic information

Components

-

-

Imidazole derivative

-

Copper ion

-

Organic acid

-

Water

-

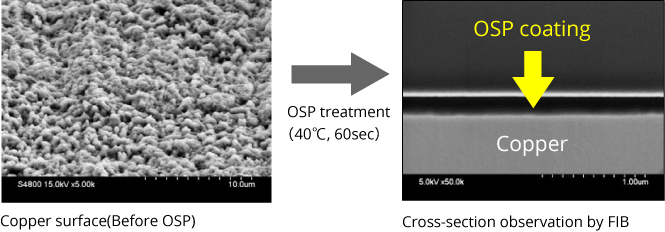

OSP coating

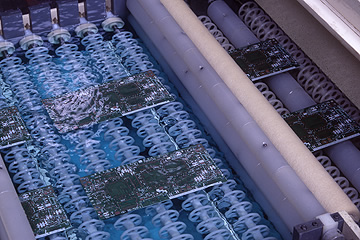

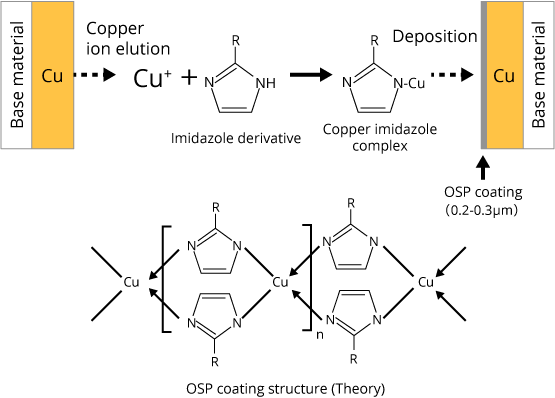

OSP is an immersion coating process.

After 30 to 90 sec immersion, 0.2 to 0.3um thickness OSP coating forms on copper surface.

Functions, Demand characteristics

Functions of OSP

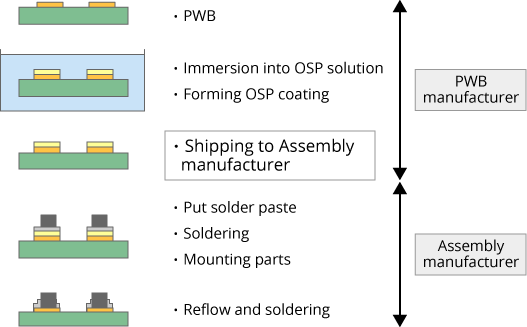

By Keeping excellent solderability, OSP acts as a bridge between PWB manufactures and assembly manufactures.

Demand characteristics of OSP (Example)

Excellent solderability

Good example

Copper surface covered by solder completely

Copper surface covered by solder completely

Bad example

Exposed copper

Exposed copper

OSP coating mechanism / OSP line

OSP coating forming mechanism (Theory)

Excellent solderability

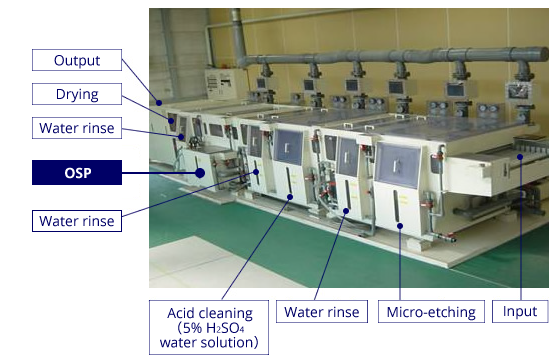

Typical OSP process